The air compressor is a wonderful device that can power a wide variety of tools. This type of equipment is expensive, but with the right maintenance schedule, you will be rewarded for years of uninterrupted use.

Whether you are buying a new or used compressor, the first step is to read the manufacturer's manual in full. There are many different types of compressors and the only way to be sure you know how to service your particular compressor is to read the original manufacturer's manual. You can also visit https:/compressedair.net.au/screw-air-compressors/ to buy screw air compressors.

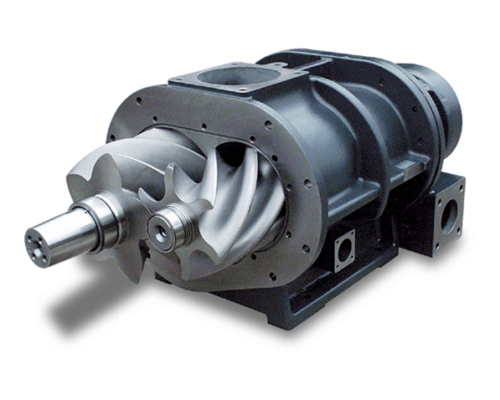

Image Source: Google

The manual should describe important factors such as the time interval between servicing, the main parts to check, and each specific type of oil to be used in the engine.

The main areas of compressor maintenance revolve around keeping key elements clean; Air inlets, hoses, air filters, fuel tanks and general exterior should be cleaned regularly to ensure optimal performance.

In addition to the cleaning mode, you should check the drain tank regularly and drain the liquid that has accumulated during normal operation. Excess fluid can usually be drained from the tank via a valve.

The compressor contains several hoses which are involved in the movement of air in the system. Most of these hoses are part of a closed system, but you still need to have them checked.

This is the most important point to consider when servicing an air compressor, but there are other things you can check for completeness.